Z-ZÉRO STUDIO

“CODE&CRAFT”

2025

Claire Dumont is a French product designer with a master's degree from the Ecole Supérieure d'Art et de Design d'Orléans and a specialised master's degree in Contemporary Creation and Technology from ENSCI-Les Ateliers in Paris. During her studies, Claire developed a passion for understanding technical objects and the concept of ‘objet technique ouvert’(open technical object).

In 2019, she founded Z-zéro, a design studio in Paris, and rethought the 3D printing process to save material, thanks to the creation of a machine and a specific parametric code.

She explores the possibilities offered by the 3D printer, from creating new structures to shaping natural materials (PLA, bioplastic or ceramic). The subjects she explores include digital manufacturing and tools, our relationship with machines or the hybridisation of digital technology and craftsmanship.

Her work has been exhibited at the Formnext trade fair in Frankfurt in 2019 (finalist in the Purmundus Challenge), at the Emergences Biennale in Pantin in 2020, during France Design Week in 2021 and 2024, and most recently at the Maison&Objet trade fair in Paris in September 2025.

In addition to her work at the studio, Claire Dumont has been teaching furniture design and parametric design at ESAD Orléans and the Ecole Supérieure de Design de Troyes for six years. She has also taught M2 Research in Design courses at ENS Paris-Saclay and ENSCI-Les Ateliers.

“Designers must understand production tools in order to create shapes that are suited to them and, conversely, think about projects in terms of how they will be manufactured.”

During my product design studies, I never once touched a 3D printer. My focus was on technical objects and our understanding of them. At the time, I thought 3D printers to be too ‘closed’ machines. As a future designer, how could I accept not understanding a tool and using it according to predefined rules simply by pressing a button? During a workshop, I had the opportunity to ‘tinker’ with a 3D printer and write code directly to control it. I finally understood this machine, and it became my field of exploration.

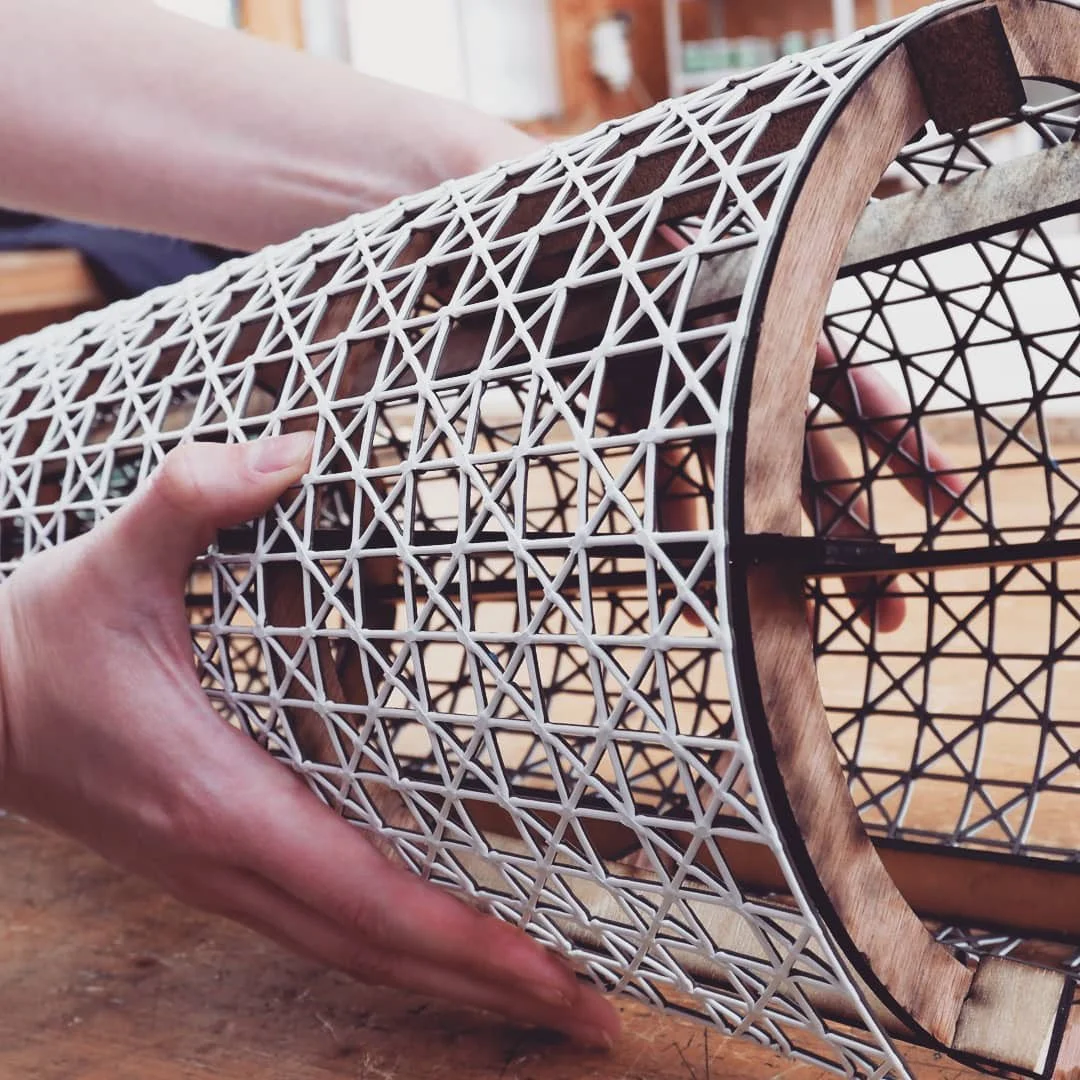

The printing process by Z-zero is based on the creation of a structural mesh that is shaped after printing. This saves on material. For this process, we designed a specific 3D printer with a large printing area (1300 x 1300 mm) and developed the code to generate the tool path. I always try to produce shapes that are only possible with the printer; I don't try to reproduce handcrafted shapes. When I print ceramics, the machine deposits a precise graphic pattern using the generated g-code, and my hands allow me to shape the volume: Code&Craft.